The components of your Dock Leveler are crucial for the efficient operation of your dock equipment. It is therefore, best for you to be familiar with each of these parts since they are common in most dock types. The elements consist of:

Bumpers

Bumpers are used to prevent vehicles from damaging the dock by driving on it. In order to prevent damage to your dock surface from overloading or collisions with other items, they equally disperse and absorb shocks from contact with cars. Additionally, they guard against vehicles colliding with bumpers at slow speeds or becoming stranded on top of them when they are no longer functional.

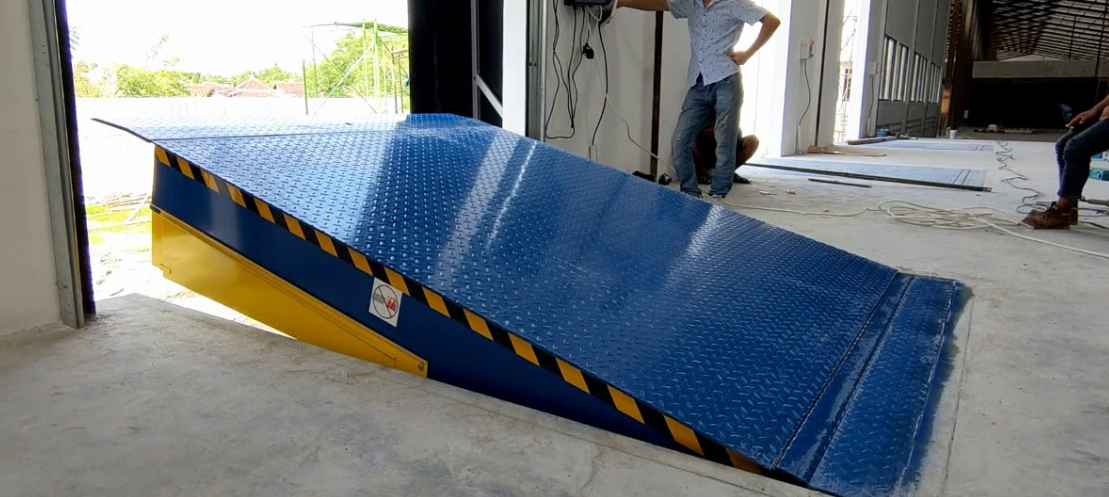

Dock Leveler Mechanism

When you click a button on the remote control or in the operator's booth, the mechanism causes the dock to rise and fall. The motor unit and gearbox are the two components that make up the mechanism. Depending on how quickly you want your dock to move, the motor can revolve at different rates thanks to the gearbox's gears. By rotating an axle connected to a chain or cable system that runs from one end of your dock to the other, the motor supplies power to move your dock up and down.

Bearing Block

One of a dock leveler's most crucial components, the bearing block safely and effectively distributes weight from your car to the ground. Your loading dock will suffer damage if this component is ineffective when in use. By keeping moisture away from the steel components in your unit, the bearing block also guards against corrosion.

Must Know Factors When Handling Dock Levelers

Dock levelers are an excellent method to manage your warehouse and handle huge loads. They are not, however, just straightforward machines that everyone may use. So, understanding the elements that affect your dock leveler's performance is crucial. These include:

Clean Floor

Maintaining a clean floor is essential to preventing dock levelers from unintentionally stumbling over it. To promote safety and prevent any mishaps, the floor must be kept in good condition. A spotless floor may also assist you keep your dock leveler from getting any dings, extending the life of your dock leveler.

Alertness

One of the most crucial aspects of using dock levelers is being aware. When using a dock leveler, you must be attentive and conscious of your surroundings. While utilizing these equipment, being aware will help you avoid getting hurt or damaging someone else. This can also assist you in preventing any potential workplace mishaps, such as one brought on by tripping over a barrier while using a dock leveler. Therefore, it is crucial for anyone operating these devices to remain vigilant at all times in order to prevent any workplace mishaps.

Loading and Unloading Correctly

To prevent damage to your items during transit, it's crucial to load and unload them properly. For simple unloading, the dock leveler should be positioned at a 30 degree angle. Additionally, consider the amount of the cargo being transported when choosing the angle. Large cars should be unloaded from trailers at an angle of 20 to 30 degrees, for instance, whereas smaller vehicles can be unloaded at a 10 to 20 degree slant.

Maintenance

To prevent the equipment from deteriorating over time and losing its efficiency, it must be regularly maintained. It is advised that you maintain your equipment regularly by looking for any damage or wear and tear on components like rollers or rubber pads that can affect how smoothly it operates while in use. You should also make sure that all screws are tightened securely to prevent the possibility of them coming loose during operation, which could lead to serious consequences.

Conclusion

Dock levelers make it possible to handle freight more successfully, and with the correct maintenance, these lifts can run without a hitch. Therefore, it is crucial for a business to have qualified dock handlers who can handle the tasks involving dock levelers such as inspections, loading, and unloading. These elements must be covered in the training provided to new workers by businesses. If personnel are not properly trained on how to handle specific situations, a lot of money will be lost from mishandling the leveler equipment.